Product description

Code:DR1500 Cable Size:50-70mm²

The DR1500 High tension Aluminium alloy anchoring clamp Retention Clip(ref. NF PA1500), suitable for retention of pre-assembled low voltage conductors and compact MV networks, capable of withstanding efforts of up to 1500 kg., Complies with all requirements of national and international standards; allows to hold 50, 54.6 (1/0 AWG) and 70 mm2 (2/0 AWG) section conductors. (diameters 11.4-14.5 mm).

They are also provided as a RETENTION KIT together with brackets, seals and fastening bolts

Material:High strength aluminium alloy,nylon plus fiber glass ,stainless steel

Product property:They are characterized by high mechanical stability ,reduced dimensions for easier handling ,high mechanical and climatic resistance .Cable gripping device in insulating material ensures the double insulation of the neutral core and avoids damage to sheath ,secured parts ,no tools required .Stainless steel bail with two marbles compressed on the end ,theis conception allows an easier locking on the body of the clalnp .They are in accordance with NFC 33-041 .

Technical specification

Dimensions | ||||

Code | DR1400 | DR1500 | DR1600 | DR2000 |

Weight | ||||

Cable Size | 50-70mm² | 50-70mm² | 50-70mm² | 70-150mm² |

Breaking Load | ||||

Specification | ||||

Use | This anchoring assembly is used for the single anchoring of A.B.C.(Aerial Bundled Conductors) with insulated neutral messenger. It comprises a bracket supporting one or two anchoring clamps. | |||

Installation | Open the screw and put conductors into grooves.Tighten the shear head nut. | |||

Standard | NFC 33-042; EN 50-483 | |||

Application

Testing

Packing&Delivery

Product Description

Glass insulator is a device used to support and insulate electrical wires. It is made from toughened glass, which enhances its strength and durability.

Currently, toughened glass insulators are among the most widely used insulators in power lines due to their excellent electrical insulation properties and mechanical strength.

ANTIFOULING(FOG) GLASS INSULATOR

Antifouling(Fog) type profiles must be used in the coast areas exposed to sea spray or very strong wind.

INSULATORS COMPONENTS

Cap and pin type of suspension glass insulator consists of the following elements: insulating part (or dielectric), pin, cap and locking device.

A locking device is a part of insulator for fixation and is manufactured of stainless steel. The assembling of an insulator is performed by cement-send mix followed by thermal wet treatment. The assembling may be performed with Portland cement or aluminosilicate cement.

A cap is for movable fixation of an insulator to another one or fittings. Caps are produced by casting from high-strength cast iron or malleable cast iron.They are made in the method of hot-dip galvanizing method to ensure its corrosion-resistant property.

Caps for DC insulators are equipped with a collar made by casting.

The insulating part is manufactured by the compaction method from low-alkali glass followed by toughening.

TECHNICAL PARAMETER

Glass insulators are a crucial component in the insulation and support of overhead transmission lines. In the early years, insulators were primarily used on power poles. However, their usages evolve to include high-voltage power line connection towers, where multiple disc-shaped insulators are hung at one end to increase the creepage distance. These insulators are commonly made of glass and are vital for maintaining insulation in power transmission systems.

ADVANTAGES OF GLASS INSULATOR

Raw Material:

Made of tempered(toughened)glass, which is more stable compared to materials used for porcelain insulators.

Suitable for various weather conditions; waterproof and moisture-proof.

Able to function normally in rainy or humid environments.

Appearance:

Glass transparency makes it easier to detect small cracks, internal defects, or damages during visual inspections.

Performance:

Excellent insulation performance and reliable operation.

High hardness, resistance to bending, and effective anti-fouling properties.

Strong mechanical and electrical performance, small size, lightweight, and long service life.

Mechanical Strength:

High mechanical strength, especially on the surface, which is resistant to cracks and slow aging.

Ease of Testing:

Preventive testing can be minimized since any damage to the glass is easily detectable during line inspections, allowing operators to identify problems visually.

Self-Cleaning Properties:

Glass insulators have smooth surfaces, which reduce the accumulation of dirt, dust, and pollutants, especially in outdoor environments. Rainwater naturally helps clean the surface, maintaining performance.

Resistant to Weathering:

Glass insulators have excellent resistance to UV radiation and other environmental factors, maintaining their strength and transparency over time without degradation.

Thermal Stability:

Glass has good thermal properties, meaning it can withstand extreme temperature variations without cracking or losing insulation properties.

Resistance to Corrosion:

Glass is highly resistant to corrosion, especially in harsh industrial or coastal environments, unlike metal components that can degrade due to chemical exposure.

Safety Factor:

In case of damage, glass insulators tend to shatter into small, blunt pieces rather than large, sharp shards. This makes them safer to handle and reduces the risk of injury during maintenance or replacement.

Environmental Friendliness:

Glass is a recyclable material, and glass insulators have a lower environmental impact in terms of disposal compared to other materials like plastics or certain ceramics.

Long-Term Cost Efficiency:

Due to their long service life and reduced need for regular preventive testing or cleaning, glass insulators can offer lower maintenance costs over time compared to other insulator types.

Testing

Packing&Delivery

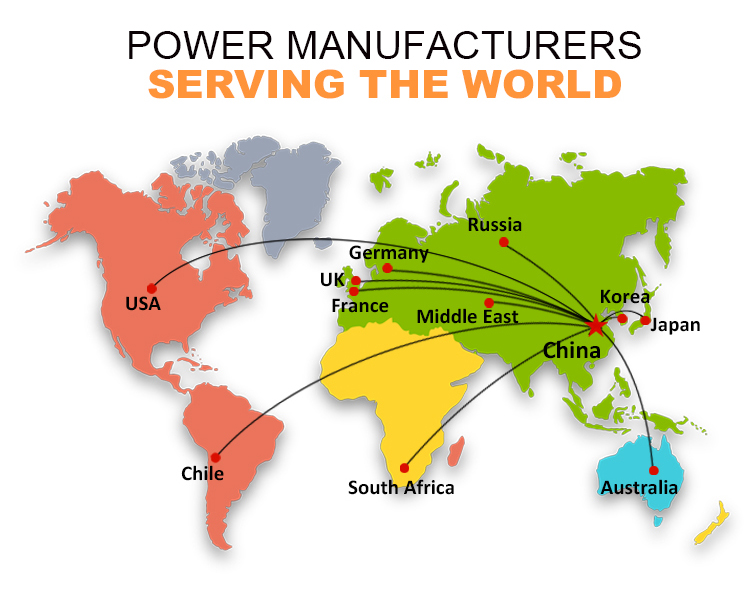

Cooperative Client

Our cooperative client are all over the world and our products are very popular all over the world. Many products are exported to Russia, USA, Australia, Canada, South Africa, Kenya, Tanzania, Zambia, Brazil and Argentina. Chile, Southeast Asian countries and other international markets. With first-class technical ability and perfect pre-sale and after-sales service guarantee system, we have established a good reputation between enterprises and users.

FAQ

Q: Do you provide sample service?

A: Yes, we only provide samples and ask for one piece at a time. The freight should be borne by you.

Q: Do you support customized services?

A: Yes, we can customize the size and logo according to your needs. Please consult the customer service for the specific minimum order quantity.

Q: How is the Design & Engineering?

A: Experienced and skilled team of designers including CAD designers and 3D designers has the capacity to deliver outstanding designs for your project. If you require more complex engineering of structures such as overhead transmission and distribution lines design,we can also provide this service also designer fee .

Q: What's the payment term?

A: We accept T/T, L/C, West Union.

Q: What's the delivery time?

A: Usually within 7-15 days according to quantities

Q: What's the standard of package?

A: Export standard package or special package as the requirement of customers.

Q: What kind of product quality your factory offer?

A: Our products with both excellent quality and competitive price. And we offer free sample for your reference.

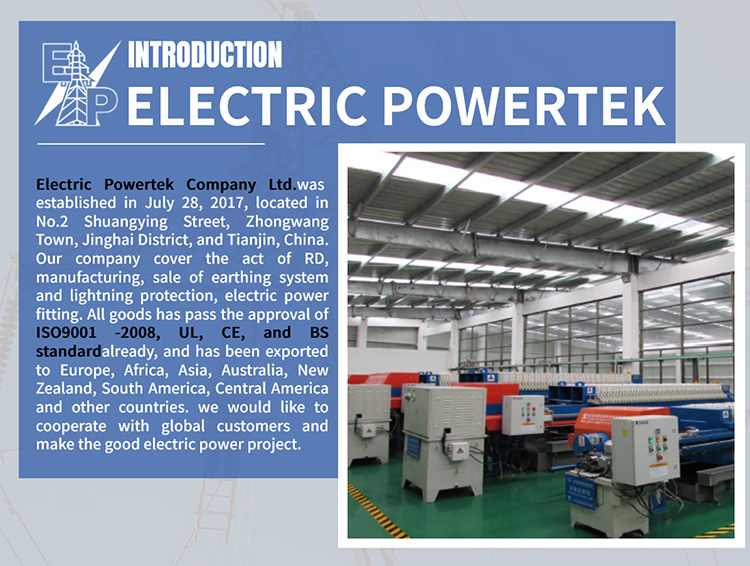

Q: What kind of certificate you have?

A: We have ISO9001:2008